Aem Read Crank Position Sensor Honda Boosted Hybrid

| | This commodity needs attention from an expert in Automobiles. The specific problem is: This article needs editing by an automotive engineer. (January 2016) |

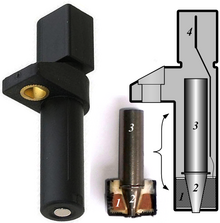

Typical inductive crankshaft position sensor

A crank sensor is an electronic device used in an internal combustion engine, both petrol and diesel, to monitor the position or rotational speed of the crankshaft. This information is used by engine direction systems to command the fuel injection or the ignition system timing and other engine parameters. Before electronic crank sensors were available, the benefactor would have to be manually adjusted to a timing marking on petrol engines.

The crank sensor can be used in combination with a similar camshaft position sensor to monitor the human relationship between the pistons and valves in the engine, which is especially important in engines with variable valve timing. This method is also used to "synchronise" a four stroke engine upon starting, assuasive the direction system to know when to inject the fuel. It is also commonly used as the primary source for the measurement of engine speed in revolutions per minute.

Mutual mounting locations include the principal creepo caster, the flywheel, the camshaft or on the crankshaft itself. This sensor is one of the 2 nigh of import sensors in modern-day engines, together with the camshaft position sensor. Equally the fuel injection (diesel engines) or spark ignition (petrol engines) is unremarkably timed from the crank sensor position signal, declining sensor volition crusade an engine non to start or will cutting out while running. Engine speed indicator takes speed indication likewise from this sensor.

Types of sensors [edit]

In that location are several types of sensors that can exist used: the anterior sensor, Hall Effect sensor, magnetoresistive sensor, and optical sensor. Inductive sensors have the simplest structure and are usually purely passive devices. Hall effect and magnetoresistive sensors take the advantage over inductive sensors in that they tin can detect static (non-changing) magnetic fields. Optical sensors do not take groovy resistance against fouling just are able to provide the most precise border detection.

Some engines, such as GM's Premium V family, use crank position sensors which read a reluctor ring integral to the harmonic balancer. This is a much more accurate method of determining the position of the crankshaft and allows the computer to make up one's mind, within a few degrees, the verbal position of the crankshaft (and thereby all connected components) at any given time.

Function [edit]

The functional objective for the crankshaft position sensor is to determine the position and/or rotational speed (RPM) of the crank. Engine Control Units utilise the information transmitted by the sensor to control parameters such as ignition timing and fuel injection timing. In a diesel fuel, the sensor will control the fuel injection. The sensor output may too exist related to other sensor data including the cam position to derive the current combustion cycle, this is very important for the starting of a four-stroke engine.

Sometimes, the sensor may get burnt or worn out - or just dice of old age at high mileage. One likely cause of crankshaft position sensor failure is exposure to extreme oestrus. Others are vibration causing a wire to fracture or corrosion on the pins of harness connectors. Many mod crankshaft sensors are sealed units and therefore will not be damaged by water or other fluids. When it goes wrong, it stops transmitting the bespeak which contains the vital information for the ignition and other parts in the system.

A bad creepo position sensor can worsen the way the engine idles, or the acceleration behaviour. If the engine is revved upward with a bad or faulty sensor, it may cause misfiring, motor vibration or backfires. Dispatch might be hesitant, and abnormal shaking during engine idle might occur. In the worst case, the car may not start.

The first sign of crankshaft sensor failure, commonly, is the refusal of the engine to start when hot but will start again once the engine has cooled.

One detail of some designs is the "three-wire" inductive crank sensor whereby the third wire is actually just a co-centric shield around the two principal sensor wires to prevent them from picking up stray electrical pulses from elsewhere in the vehicle engine bay.

Examples [edit]

Some other type of crank sensor is used on bicycles to monitor the position of the crankset, usually for the cadence readout of a cyclocomputer. These are ordinarily reed switches mounted on the bicycle frame with a corresponding magnet attached to one of the pedals crankset arms.

Notes [edit]

GMR (behemothic magnetoresistance) technology is also used for Creepo, Cam rotor sensing purpose. Mitsubishi is the first who used this technology in automotive awarding purpose.

External links [edit]

- Crankshaft & Camshaft Position Sensors

- Crank Position Sensor

Source: https://en.wikipedia.org/wiki/Crankshaft_position_sensor

0 Response to "Aem Read Crank Position Sensor Honda Boosted Hybrid"

Post a Comment